剑桥大学研究人员开发出了一种制造自适应生态友好型传感器的方法,这种传感器可以直接印在各种生物表面上,如手指、花瓣,而且不易被察觉。

Researchers have developed a method to make adaptive and eco-friendly sensors that can be directly and imperceptibly printed onto a wide range of biological surfaces, whether that’s a finger or a flower petal.

研究人员从可以贴合和粘附于各种表面的蜘蛛丝获得灵感,开发出了这种方法。这些“蜘蛛丝”还结合了生物电子学,实现了在“网”上添加不同的传感功能。

The method, developed by researchers from the University of Cambridge, takes its inspiration from spider silk, which can conform and stick to a range of surfaces. These ‘spider silks’ also incorporate bioelectronics, so that different sensing capabilities can be added to the ‘web’.

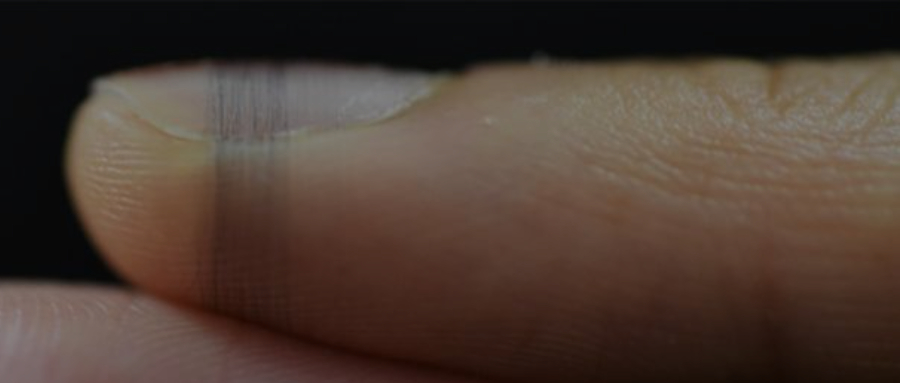

这种“蜘蛛丝”纤维比人的头发至少还细50倍,并且重量非常轻,所以研究人员可直接将其印制在蓬松的蒲公英花头上而不会破坏其结构。当印在人体皮肤上时,纤维传感器会紧贴皮肤并露出汗孔,因此佩戴者不会察觉到它们的存在。对印制在人体手指上的纤维进行的测试表明,它们可以用作持续健康监测器。

The fibres, at least 50 times smaller than a human hair, are so lightweight that the researchers printed them directly onto the fluffy seedhead of a dandelion without collapsing its structure. When printed on human skin, the fibre sensors conform to the skin and expose the sweat pores, so the wearer doesn’t detect their presence. Tests of the fibres printed onto a human finger suggest they could be used as continuous health monitors.

这是一种废弃物少、排放低的生物结构增强方法,可用于从医疗保健、虚拟现实到电子纺织品、环境监测等一系列领域。该研究成果已发表于《自然电子学》杂志。

This low-waste and low-emission method for augmenting living structures could be used in a range of fields, from healthcare and virtual reality, to electronic textiles and environmental monitoring. The results are reported in the journal Nature Electronics.

虽然人类皮肤非常敏感,但通过电子传感器增强,可能会从根本上改变我们与周围世界互动的方式。例如,将传感器直接贴在皮肤上可用于持续健康监控,了解皮肤感觉,或者改善游戏或虚拟现实应用中的“现实”感。

Although human skin is remarkably sensitive, augmenting it with electronic sensors could fundamentally change how we interact with the world around us. For example, sensors printed directly onto the skin could be used for continuous health monitoring, for understanding skin sensations, or could improve the sensation of ‘reality’ in gaming or virtual reality application.

智能手表等嵌入传感器的可穿戴设备已经广泛普及,但佩戴这些设备可能并不舒适,存在感过强,并且可能抑制皮肤本身的感觉。

While wearable technologies with embedded sensors, such as smartwatches, are widely available, these devices can be uncomfortable, obtrusive and can inhibit the skin’s intrinsic sensations.

“如果你想准确地感知皮肤或树叶等生物表面的任何东西,那设备和表面之间的接触面至关重要,”引领这项研究的剑桥大学工程系教授黄艳燕(Yan Yan Shery Huang)说。“我们也希望这些生物电子设备能够完全不被使用者察觉,这样就不会干扰用户与世界的互动方式。同时,我们希望它们是可持续的、废料少的。”

“If you want to accurately sense anything on a biological surface like skin or a leaf, the interface between the device and the surface is vital,” said Professor Yan Yan Shery Huang from Cambridge’s Department of Engineering, who led the research. “We also want bioelectronics that are completely imperceptible to the user, so they don’t in any way interfere with how the user interacts with the world, and we want them to be sustainable and low waste.”

有很多种方式制作可穿戴传感器,但是每种都有缺陷。比如说柔性电子,通常印在不透气、不透湿的塑料薄膜上,会让皮肤感觉好像被保鲜膜裹住一样。其他研究者最近开发了具有透气性的柔性电子,类似人造皮肤,不过依旧会干扰正常的感觉,且依赖于能源和废料密集型制造技术。

There are multiple methods for making wearable sensors, but these all have drawbacks. Flexible electronics, for example, are normally printed on plastic films that don’t allow gas or moisture to pass through, so it would be like wrapping your skin in cling film. Other researchers have recently developed flexible electronics that are gas-permeable, like artificial skins, but these still interfere with normal sensation, and rely on energy- and waste-intensive manufacturing techniques.

3D打印技术是生物电子学另一条潜在的可行之路,与其他技术相比,它不会那么浪费,但是所制作的设备也会更加笨重,影响日常行动。纺织电子纤维对于使用者来说几乎感觉不到,但是敏感度和精确度都不高,而且很难转移到所需物体上。

3D printing is another potential route for bioelectronics since it is less wasteful than other production methods, but leads to thicker devices that can interfere with normal behaviour. Spinning electronic fibres results in devices that are imperceptible to the user, but don't have a high degree of sensitivity or sophistication, and they’re difficult to transfer onto the object in question.

现在,这支由剑桥大学牵头的团队开发了一种制作高性能生物电子器件的新方法,可以直接打印到各种生物表面,从指尖到蒲公英的绒毛种球都可以定制。他们的技术灵感部分来源于蜘蛛,蜘蛛能够用最少的材料,创造出适应周围环境的精密而结实的网状结构。

Now, the Cambridge-led team has developed a new way of making high-performance bioelectronics that can be customised to a wide range of biological surfaces, from a fingertip to the fluffy seedhead of a dandelion, by printing them directly onto that surface. Their technique takes its inspiration in part from spiders, who create sophisticated and strong web structures adapted to their environment, using minimal material.

研究团队使用PEDOT:PSS(一种生物相容性导电聚合物)、透明质酸和聚氧化乙烯制造生物电子“蜘蛛丝”。这种高性能纤维是在室温下用水基溶液制成的,研究人员进而能够控制其“可纺性”。他们设计了一种轨道纺丝方法,使纤维可以变形以贴合生物表面,甚至包括指纹等微观结构。

The researchers spun their bioelectronic ‘spider silk’ from PEDOT:PSS (a biocompatible conducting polymer), hyaluronic acid and polyethylene oxide. The high-performance fibres were produced from water-based solution at room temperature, which enabled the researchers to control the ‘spinnability’ of the fibres. The researchers then designed an orbital spinning approach to allow the fibres to morph to living surfaces, even down to microstructures such as fingerprints.

测试显示,在人类手指、蒲公英种球等表面上,生物电子纤维体现了其优质的传感器性能,且宿主对此几乎毫无感觉。

Tests of the bioelectronic fibres, on surfaces including human fingers and dandelion seedheads, showed that they provided high-quality sensor performance while being imperceptible to the host.

“不论是在微观还是宏观层面,我们的纺织方法让生物电子纤维不必进行任何图形辨识,就能遵循不同形状的解剖结构。”该论文第一作者Andy Wang表示,“这开辟了一个制造可持续电子设备和传感器的全新视角,是一种更容易生产大面积传感器的方式。”

“Our spinning approach allows the bioelectronic fibres to follow the anatomy of different shapes, at both the micro and macro scale, without the need for any image recognition,” said Andy Wang, the first author of the paper. “It opens up a whole different angle in terms of how sustainable electronics and sensors can be made. It’s a much easier way to produce large area sensors.”

大多数高分辨率传感器都是在工业洁净车间中制成的,并且需要使用有毒化学品,过程里步骤繁琐且需要消耗大量能源。而剑桥大学开发的传感器可以在任何地方制造,并且所需能源仅为普通传感器的一小部分。

Most high-resolution sensors are made in an industrial cleanroom and require the use of toxic chemicals in a multi-step and energy-intensive fabrication process. The Cambridge-developed sensors can be made anywhere and use a tiny fraction of the energy that regular sensors require.

生物电子纤维可以修复,在达到使用寿命之后,可以轻易洗掉,产生的废弃物不足一毫克。相较之下,平时洗一次衣服就会产生600到1500毫克的纤维废弃物。

The bioelectronic fibres, which are repairable, can be simply washed away when they have reached the end of their useful lifetime, and generate less than a single milligram of waste: by comparison, a typical single load of laundry produces between 600 and 1500 milligrams of fibre waste.

“使用我们简易的制造技术,我们几乎可以将传感器放在任何地方,并在需要的时候随时随地对其进行维修,不需要大型打印机或集中制造设备,” 黄艳燕说,“这种传感器可以直接在需要的地方按需制作,并且产生的废弃物和排放量极少。”

“Using our simple fabrication technique, we can put sensors almost anywhere and repair them where and when they need it, without needing a big printing machine or a centralised manufacturing facility,” said Huang. “These sensors can be made on-demand, right where they’re needed, and produce minimal waste and emissions.”

研究者表示,他们的设备可以用于健康监控、虚拟现实、精准农业和环境监测。未来,这种纤维打印方法还可以加入其他功能性材料,建立集成纤维传感器,从而增强生命系统的显示、计算和能量交换功能。这项研究已经产业化,并得到剑桥大学的产业化部门“剑桥企业”(Cambridge Enterprise)的支持。

The researchers say their devices could be used in applications from health monitoring and virtual reality, to precision agriculture and environmental monitoring. In future, other functional materials could be incorporated into this fibre printing method, to build integrated fibre sensors for augmenting the living systems with display, computation, and energy conversion functions. The research is being commercialised with the support of Cambridge Enterprise, the University’s commercialisation arm.